- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

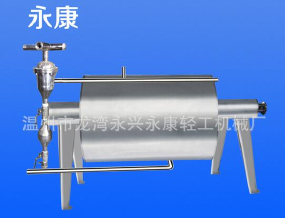

- Place of Origin: WENZHOU

- Brand Name: YONGKANG

- Model Number: C66

Because this uses reverse heat exchange principle, segmented preheating, sterilization, make the material preheating first to give short-term, short-term sterilization Finally, having:

Features one: between material and medium plus perform a small temperature difference, sterilization time is short (<8 seconds) after the coke material handling without bitterness, the physical and chemical indicators of loss kept to a minimum.

Features 2: steam consumption of small, high thermal efficiency, optimal energy efficiency, without having to install the condensate trap outlet, condensate temperature is only 70-80 ℃.

Features 3: Open the door structure and cover straight tube feeding tube, clean simple, easy, and intuitive, no thorough cleaning is not the concern.

Machine installation:

a) machine installation site together with the best pool material or drums, and drum cooler or keep short distance. And feed pail in the pool or look for easy operation, and keep close to the drum lid to avoid back pressure caused by high leakage. Usually keep the highest drum about 8 meters, no more than 20 m long pipe is appropriate.

b) the discharge tube is preferably rubber tube, and the tube is not easy scaling, and insulation properties or. The discharge nozzle should be higher than 1-2 meters above the sterilizer.

c) The machine should be installed flat, allowing the tilt of 0.5 degrees, from the ground plane 50-200 mm is appropriate.

d) the condensate drain line should have three or more ferrule receiving sewers and outdoor use rubber tube. Users need to be recovered in distilled water, the outlet pipe can be connected directly open container.

Fourth, the machine uses:

a) Open the feed valve and flow valve ① ③, open feed pump to feed from the slot pool to sterilization cycle, open and adjust the steam valve ④, so that the material temperature thermometer display the desired sterilization temperature, and then close the reflux valve ③, open the outlet valve ②, the machine began to work, back pressure table shows the spout tube after pressure loss and a discharge nozzle height.

b) should be ended immediately into the cooling water or sterilized water color, about 20 to 40 seconds after the tube material have been pushed out, and then open the reflux valve ③, close the discharge valve ②, cooling cycle and the temperature dropped to 40 ℃. Then open the sterilizer cover up and down rows back and forth scrub with a brush tube 3-5 times (Note: Application of flushing water lubricated rubber tube inserted into the available positions within the four tube in which a)

c) Rinse once per shift and can make the material within easy scaling, increase the sterilization effect.

d) open the inlet valve ⑥ pressed into the water through the water return pipe up, this will prevent the release of insulation material in the preheat tube resulting residue was coking junction fouling.

V. Note:

a) stringent condensate outlet valve installation.

b) steam valve must not leak, when not in use is also likely to cause the heat transfer tubes into the steam leaking.

c) Open the door seal rubber frequently changes, otherwise perishable lid and leakage of material.

d) during normal operation at both ends before sterilization Open the door does not stop people, in order to avoid accidental leakage of hot material injury.

Sixth, machine maintenance and repair:

1. The top of the machine stringency wash with water to prevent water leakage into the machine, affect the insulation effect, and in severe decay machine.

2. Note that the machine thermometers, pressure gauge display is correct inaccurate shall be promptly replaced.

3. Open the door gasket cover wearing parts, must be replaced when damaged and leakage of material (under normal circumstances, the gasket replaced every two years).

- Place of Origin: WENZHOU

- Brand Name: YONGKANG

- Model Number: C66